Best Solution For 3 Dimensional Engraving on a multitude of a metallic surface without a chip & with Zero Running cost on Tools. It is possible by 3D Laser Engraving Machine. This machine allows you to transfer your art, lettering designs onto a wide range of materials like silver, gold, aluminum, etc work on different surfaces, whether flat, conical or curved such as rings and charms for the jewelry sector, metal stamps or dies, medallions, etc.

Are you wondering what is engraving!! If Yes Read On.

Laser Engraving

Laser engraving is the technique which is used to leave marks on an object or to personalize an object with a logo or a brand or a name of some sort you can even mark your favorite pics. The technology does not use any type of ink or pads.

Laser engraving gives a beautiful and attractive impact on your product.it involves removing a part of the surface (flat, curved or conical) in definite deepness. In laser engraving, the laser beam directed on the product burns off the surface hence the engraved pattern is permanent.

The advantage of the machine is the material will never lose its mark in any condition. 3D Laser Engraving Machine engraves the serial numbers, time stamps, part number, component labels, bar codes, Data matrix code marking, certified marks, branding, and industry-specific codes.

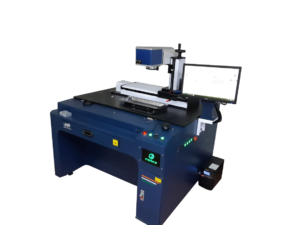

3D laser Engraving Machine

This machine is specialized in engraving and creating a 3D images on a wide range of materials like silver., gold brass, copper, aluminum, stainless steel(ss), mild steel(ms), acrylics, etc. It is mostly used for coin mould, die mould, medallions, etc. The machine can be used for intricate, minute detailing on moulds for shoes lower design engraving, furniture, handles, and knobs. The applications are as vast as the imagination of the user.

This machine has an internal lens that allows us to play with different focal lengths automatically and it also improves the production time by not having to ta ke it manually. This lens moves to different dimensions which are pre-programmed in the software, achieving a higher quality finish and accuracy. Laser engravers use fiber-optic lasers for excellent precision and rapid speed. They are known as long-lasting systems that require little maintenance and can provide consistent results.

ke it manually. This lens moves to different dimensions which are pre-programmed in the software, achieving a higher quality finish and accuracy. Laser engravers use fiber-optic lasers for excellent precision and rapid speed. They are known as long-lasting systems that require little maintenance and can provide consistent results.

Through this machine, you are capable to give the depth to different metals, ranging from a few microns to a few millimeters

Features Of 3D Laser Engraving Machine

- Work on X, Y & Z-axis.

- Engrave all files at once

- Superior in speed, quality and laser power

- Mark on flat and 3d surfaces

- Permanent marking

- Easy to operate

- High speed and precision

- Engrave Wide range of material like steel, gold, silver, etc

- Clear and safe process

- Engrave deep and fine

Difference between 2D & 3D Fiber laser Engraving Machine

- SCANNER HEAD – IN 2D Machine Scanner head has 2 mirrors & In 3D Machine have 3 mirrors

- 3D Machine have Dynamic focusing as compare to 2d machine

- DIMENSIONS-3D machine move X, Y & Z axis dimensions and 2D machine move only X &Y-Axis.

- 2 D machine move forward & 3D machine moves forward and backward also

3D Laser Engraving Machine is able to engrave or mark on flat and non-flat surfaces.

- Triangular Surface

- Sloped and slanted Surfaces

- Cylindrical Shapes

- Spherical and round Shapes

- Conical Shapes.

The 2D laser engraving machine can only work on a flat surface if you want to engrave on the round surface, spherical, conical or irregular surface.3D Laser Engraving Machine is your BEST CHOICE.

To know more about our company and machines:-

SUSCRIBE*LIKE*SHARE*RATE

Google Review –Instagram –Facebook – Twitter –Blogger Page –YouTube – Linkedin

For more info contact us:

ADDRESS: H-58 Site-V Kasna, Industrial Area, Greater Noida, Uttar Pradesh 201310

PHONE: +91-8527928301,8588867021/27

@barkha