Cutting of metals in different shapes and sizes were always a challenge for the manufacturing industry.

Desire to optimize on cutting time, minimize on wastages and to find one single machine for multiple types of metals with varied wall thickness was always a dream. TODAY FIBER LASER CUTTING TECHNOLOGY not only fulfills that dream but does much more.

To know the highlights and insights regarding the Fiber Laser Cutting Machine, let us first know what Laser Cutting machine is?

How Laser cutting machine works??

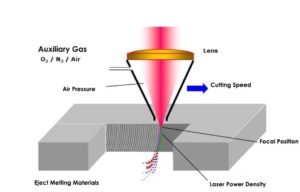

Fiber laser cutting works by focusing the power of a high power laser onto the surface of thermal to be cut. The energy in the laser beam is absorbed into the surface of a material and the energy of the laser is converted into heat which melts or vaporizes the material. Additionally, gas is focused or blown into the cutting region to expel or blow away the molten metal and vapor from the cutting path.

Laser cutting machines are widely used for metal sheet processing, advertising, trademark, kitchenware, cars, mechanical knife tool, electronic parts, elevators passage, signage, electric panels, etc

Metal fiber laser cutting machines are programmed to automatically control various laser parameters, such as beam power and profile. There are also other settings that can affect the quality of the cut and the technician or machine operator can configure it manually:

- Alignment of the laser beam

- Focal length

- Nozzle Centering

- Nozzle Distance

- Cutting Speed

- Laser Frequency

Most of these parameters are programmed automatically, there are three that should be adjusted to improve the cutting quality and thus avoid burr: GAS PRESSURE, FOCAL LENGTH & CUTTING SPEED.

Principle:- Laser cutting machine is based on a high strength laser beam, supplemented by high-pressure gas to blow out molten slag.

Environmental Protection:- Laser cutting machine depends on optical energy compared with plasma machine, its energy is cleaner and there is no dust and no arc overflow.

Fiber Laser Cutting Machine be used in various industries like the automotive industry, advertising industry, kitchenware industry, sheet metal industry, fitness equipment industry, Decoration industry, etc

Metal Fiber Laser Cutting Machine has the incomparable flexibility and processing precision of the traditional processing method because it uses ” contactless processing ” method that does not need mold making and additional expense. Therefore, fiber laser cutting technology can effectively improve product quality, reduce production costs, diminish labor intensity & improve traditional sheet metal processing technology.

Emtex manufacturers laser cutting machine with high productivity and upper segment standards. It is a non-contact cutting machine which is itself has multiple benefits including reduced downtime and increased profits due to highly accurate performance. It allows the processing of highly reflective material too. Fiber Laser cutting machine has higher wall-plug efficiency. Fiber Laser Metal Cutting Machine doesn’t get in contact with the materials, which means there is no wear and tear of a tool, the cost of reestablishing tool is zero.

OUTSTANDING ADVANTAGES OF EMTEX FIBER LASER CUTTING ARE:-

- Cost-saving on power consumption

- Ease of operation

- Control the air pressure automatically

- Saves energy and time

- Lifetime over 80000 hours of laser module life

- Maintenance-free operation

- Excellent Beam Quality

- Extremely fast Cutting Speed

- High Stability

- No Tool Wear and low maintenance costs

- High positioning accuracy and smooth cutting surface

To know more about our company and machines:-

SUSCRIBE*LIKE*SHARE*RATE

Google Review –Instagram –Facebook – Twitter –Blogger Page –YouTube – Linkedin

For more info contact us:

ADDRESS: H-58 Site-V Kasna, Industrial Area, Greater Noida, Uttar Pradesh 201310

PHONE: +91-8527928301,8588867021/27

@barkha